Products

Molded Pulp

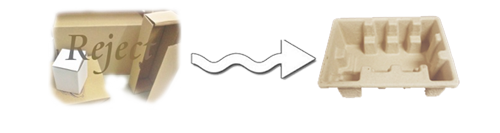

Molded pulp is a sustainable packaging material, typically made from recycled paperboard & newsprint, can be recycled again after is useful life cycle. It is used for protective packaging, food service trays and beverage carriers.

The process involve vacuum forming and transfer molds, where the mold is an extremely fine wire mesh in the shape of the upper/exposed surface. The fibrous slurries are frequently made up of a high percentage or entirely of recycled paperboard & newspaper, which produces a relatively smooth surface on one side and a fairly smooth surface on the opposite side with good accuracy and definition.

Process flow:

- Pulping

- Forming

- Nature or hot air oven drying

- Hot press — with or without emboss

- Trimming — depend on product application

- Packaging

- Delivery

Why pulp mold?

- 100% post consumer waste with biodegradable properties, Non toxic & No waste & pollution

- Cost effective — less expansive compare to expanded polystyrene (EPS), vacuumed formed (PET)

- and PVC, corrugation and foams

- Space saving design — smaller in size resulting lower shipping cost & warehousing cost, 100% retrievable

- Conforms to ISO 9001 & ISO 14001 standard

- Good resistant to shock, crushing resistant and buffer capacity

- Water resistant & temperature resistant

- Go GREEN and promote company image, less taxation for EU market & no CFC damage to ozone

Pulp production machinery

- 1x pulper

- 2 x forming machine

- 1x thermo oil drying system

- 4 x 20 mt hot press machine

- 2 x 20 hp trimmer

Present capacity: 10,000 pcs daily